The energy monitoring system manageENERGY according to ISO 50001

With structured energy monitoring, you reduce costs and use resources sustainably.

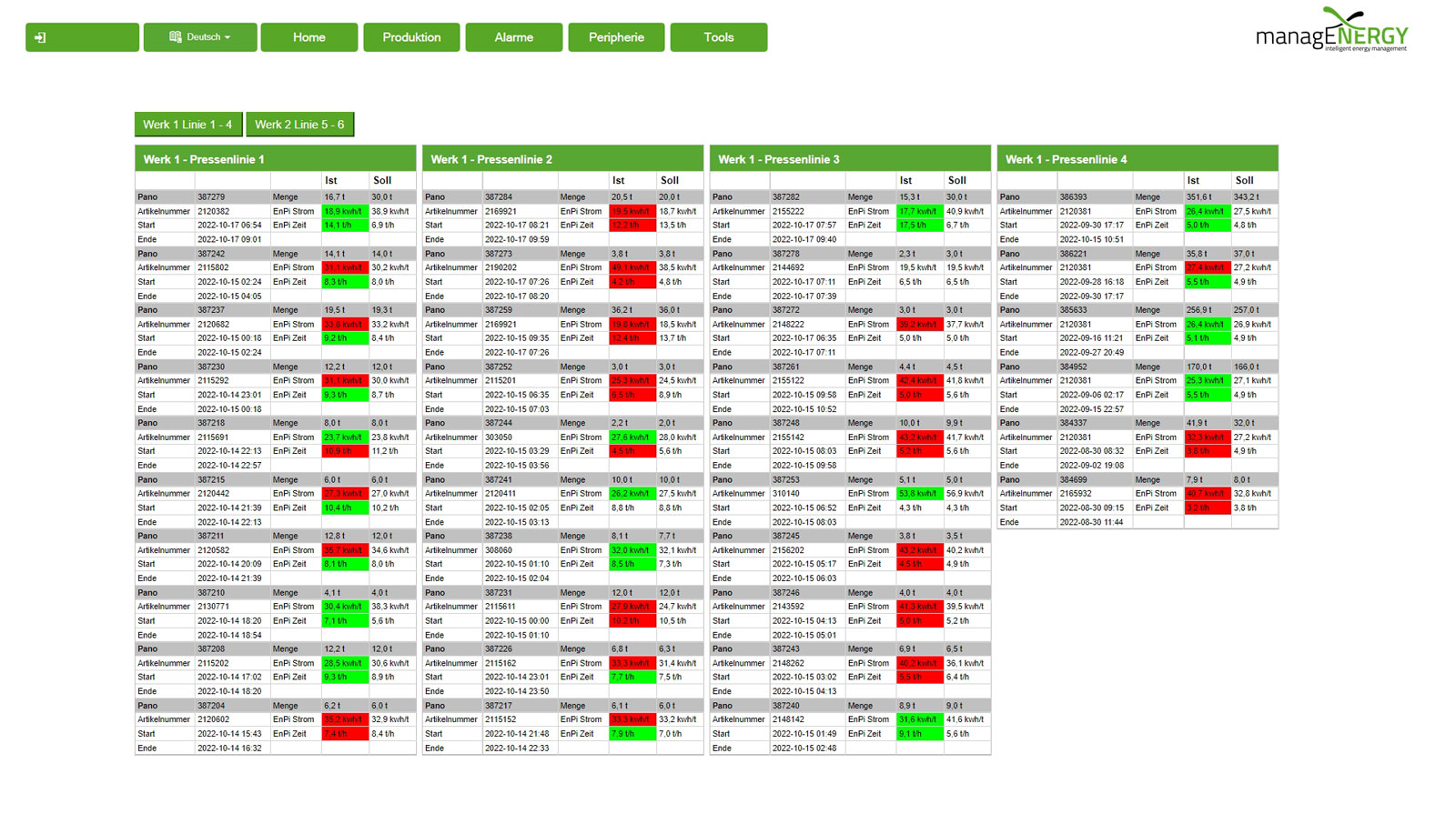

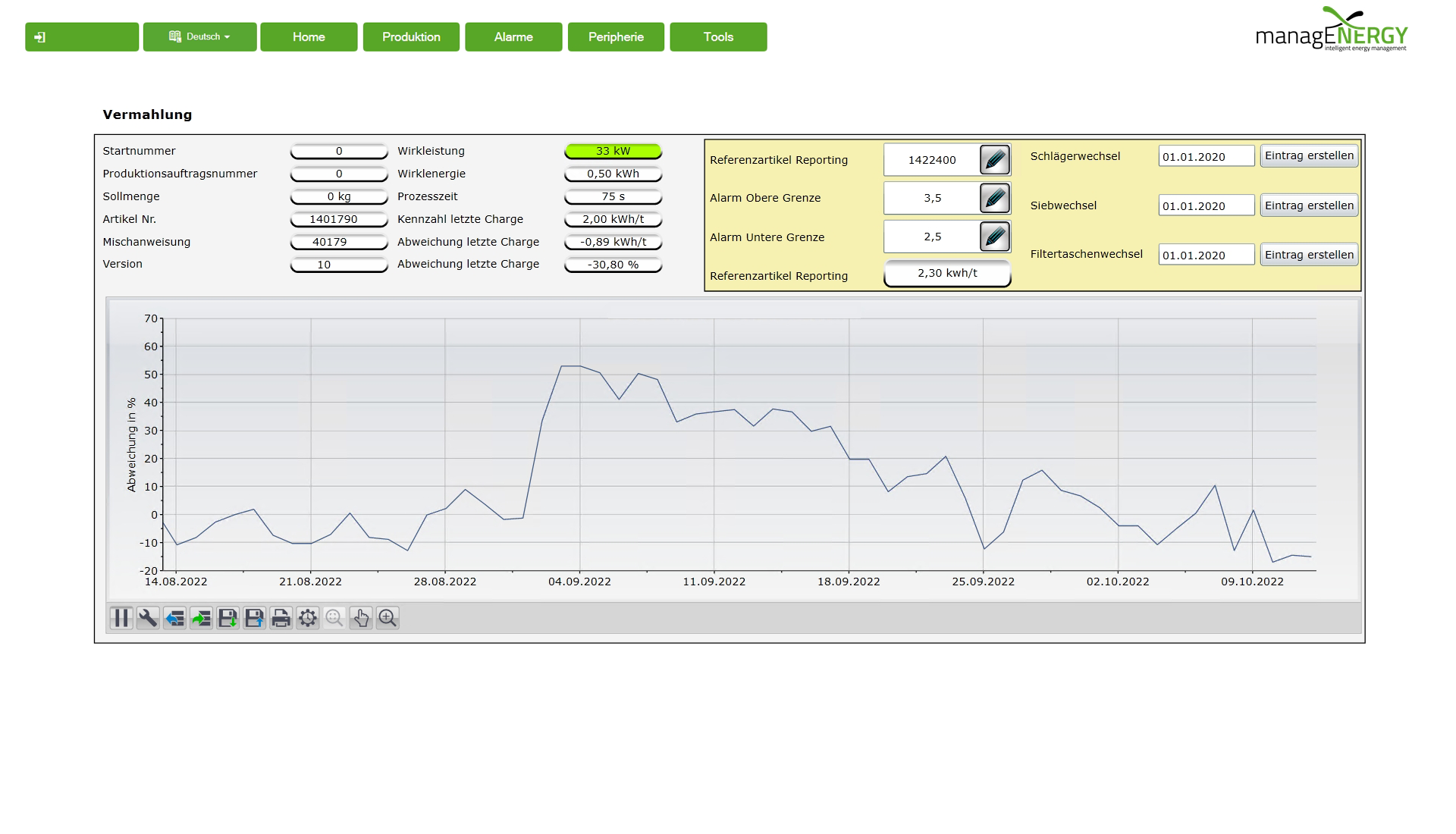

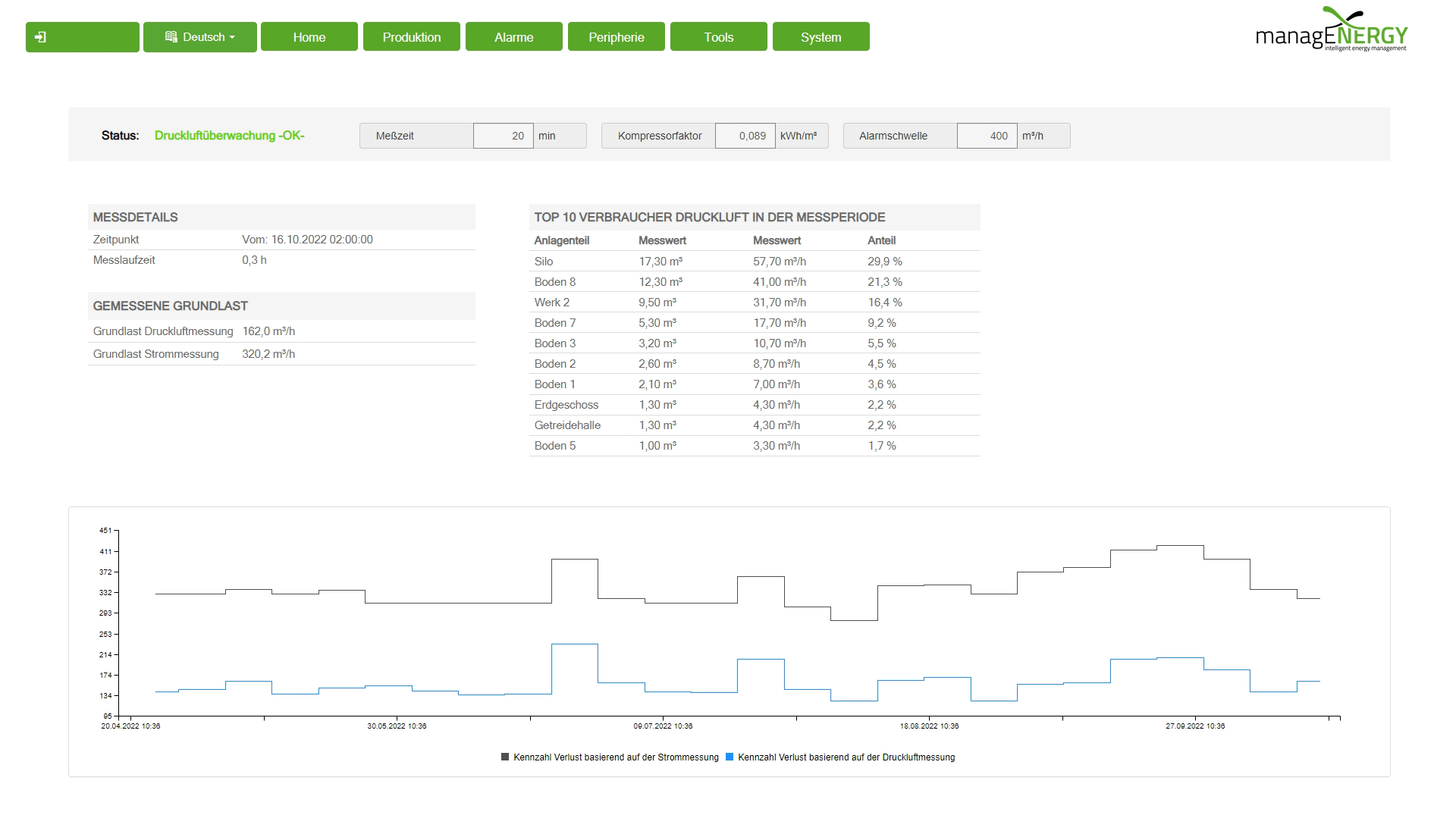

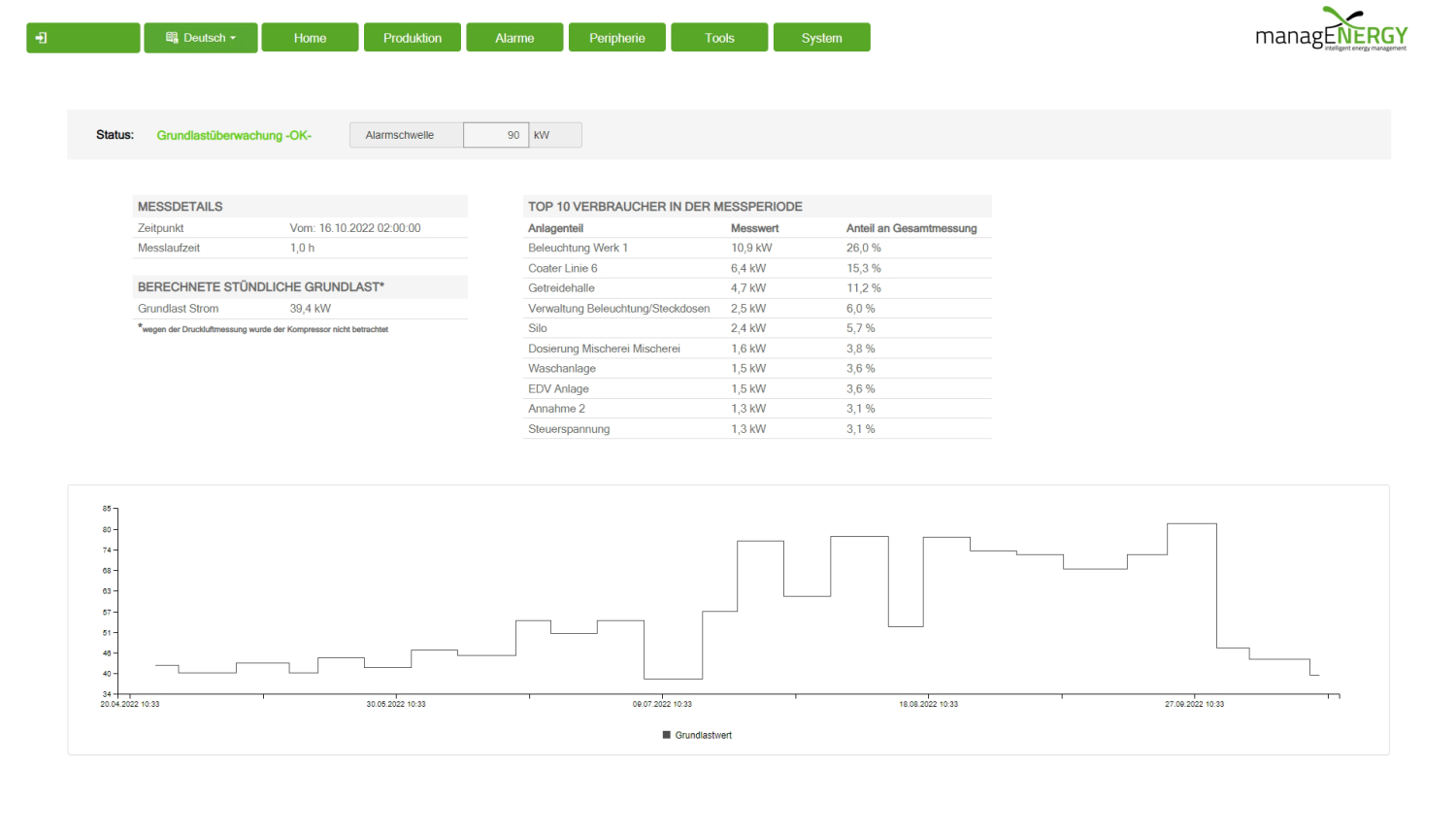

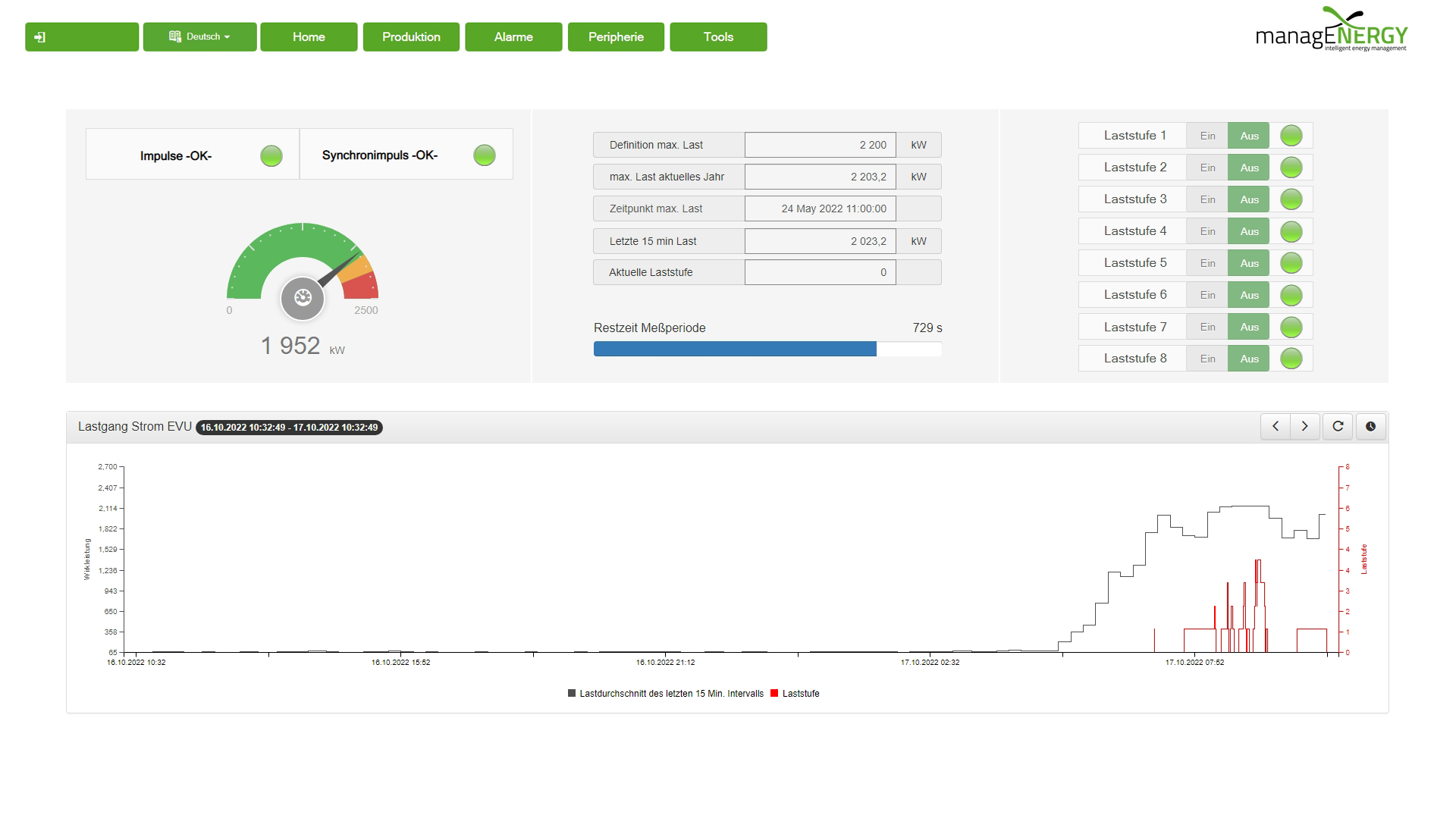

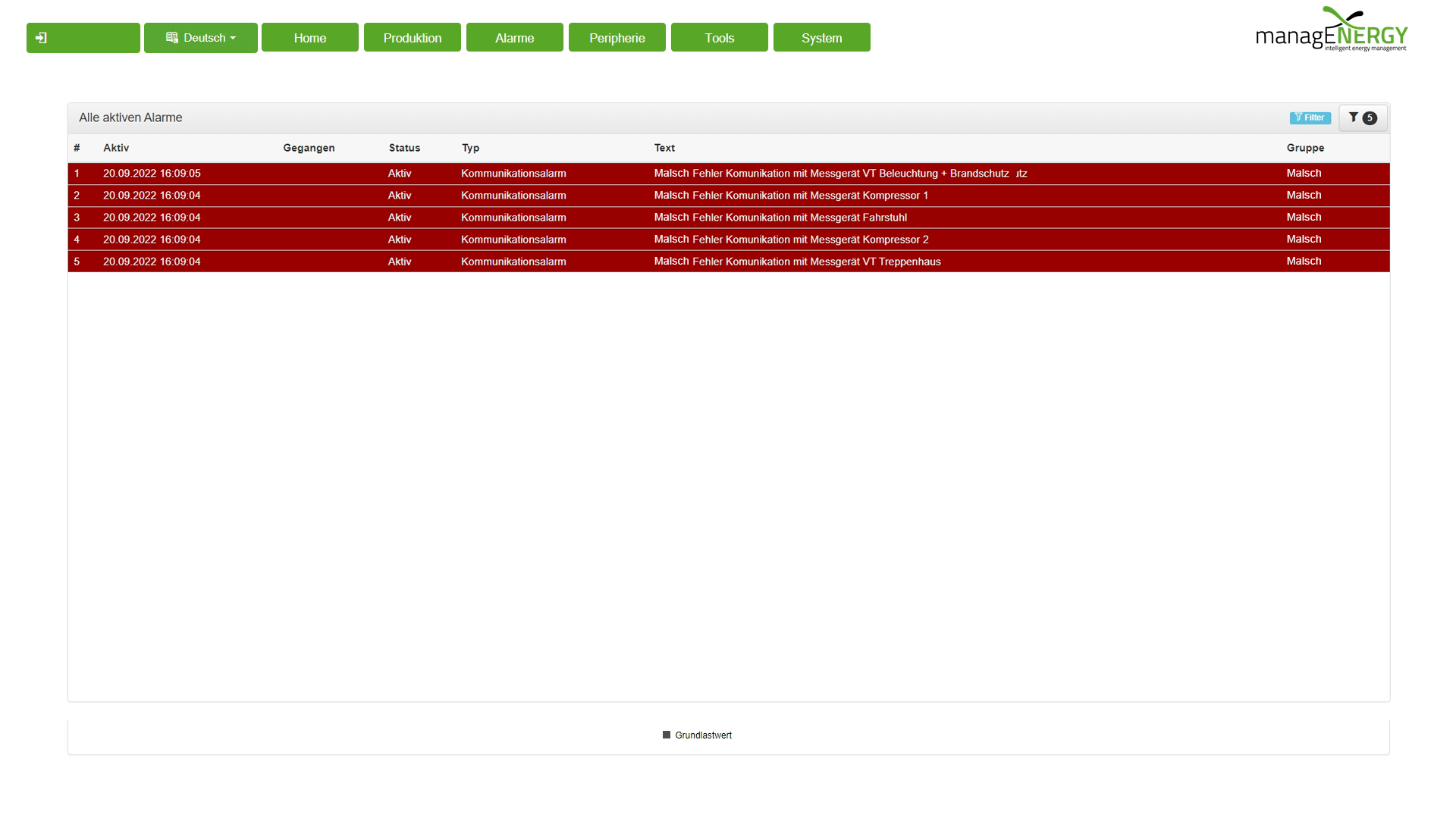

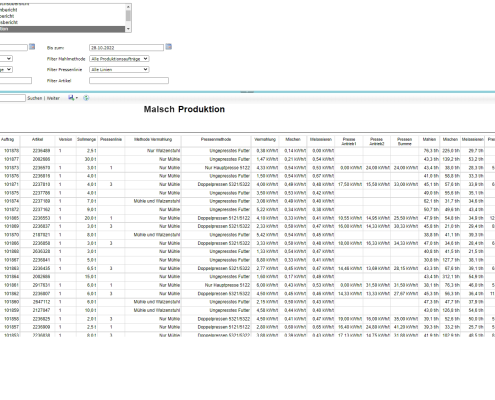

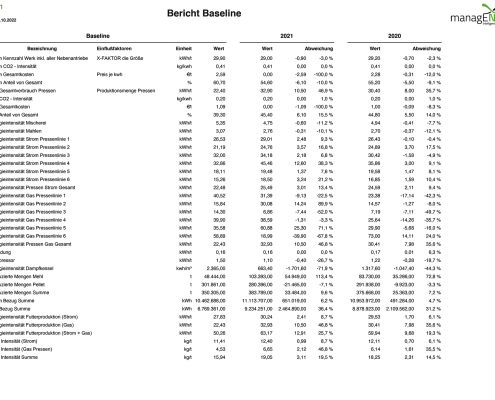

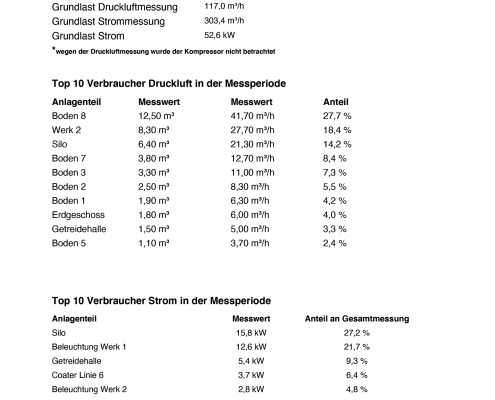

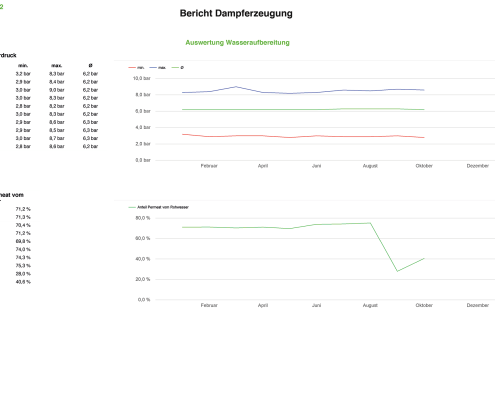

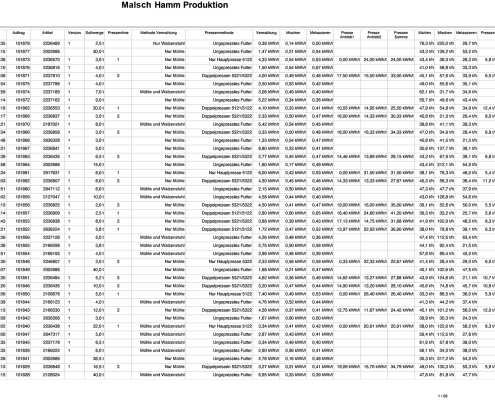

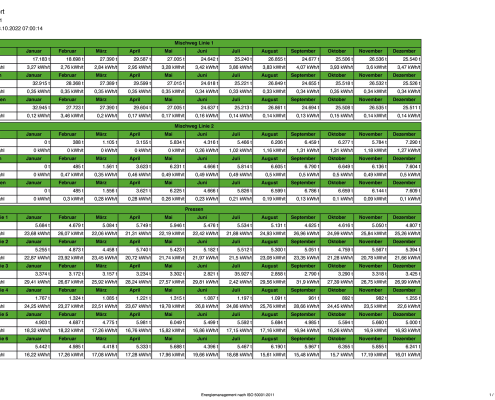

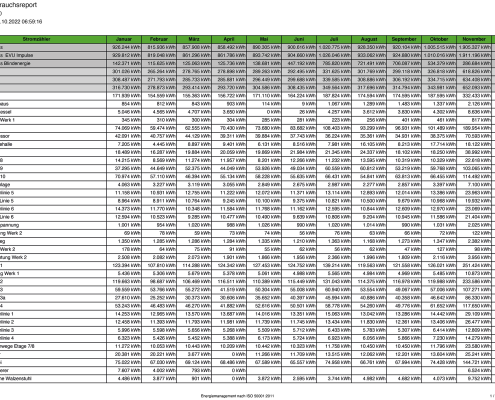

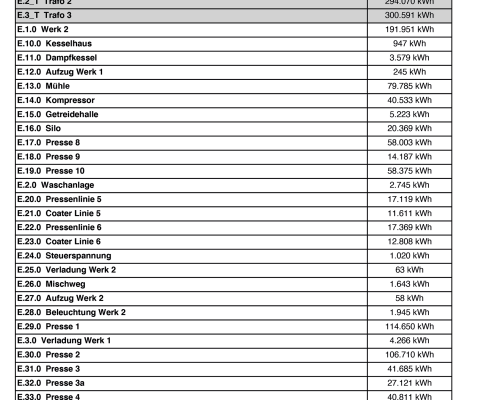

With the energy monitoring system managENERGY, energy costs of electricity, steam, water and heat can be permanently reduced. Our versatile energy monitoring system managENERGY according to ISO 50001 is adapted to your needs to identify energy and process-based potentials. You get maximum transparency about your energy consumption and CO2 emissions. Transparency leads to more efficiency and more productivity. We accompany you throughout the entire optimization process for continuous cost reduction.

Energy management is the basis for efficient and careful use of environmental resources.

ISO 50001 – ENERGY MANAGEMENT

ManagENERGY is an eligible energy monitoring system according to ISO 50001!